-

FANGUARD®

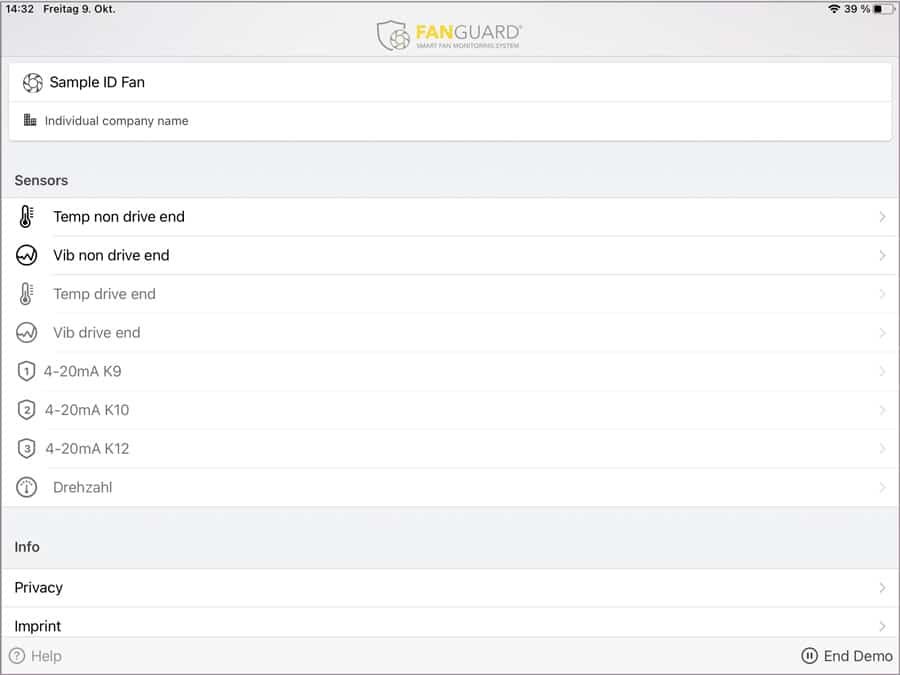

SMART FAN MONITORING SYSTEM

Find a contact person play_arrowWatch video -

-

Intelligent system for digital monitoring

-

For you as a plant operator, this means: Higher competitiveness through reduction of maintenance costs, optimization of maintenance strategies and avoidance of plant downtimes through 24/7 monitoring.

- Higher productivity through optimized maintenance

- Cost reduction through avoidance of downtimes

- Fast reaction to malfunctions

- Digital control rounds

- Important information immediately & paperless

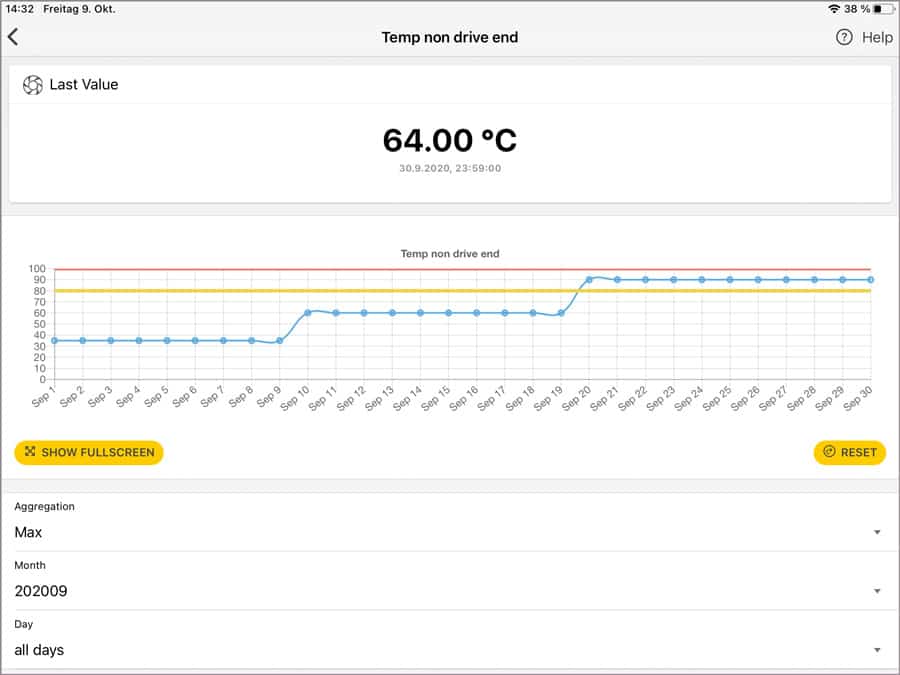

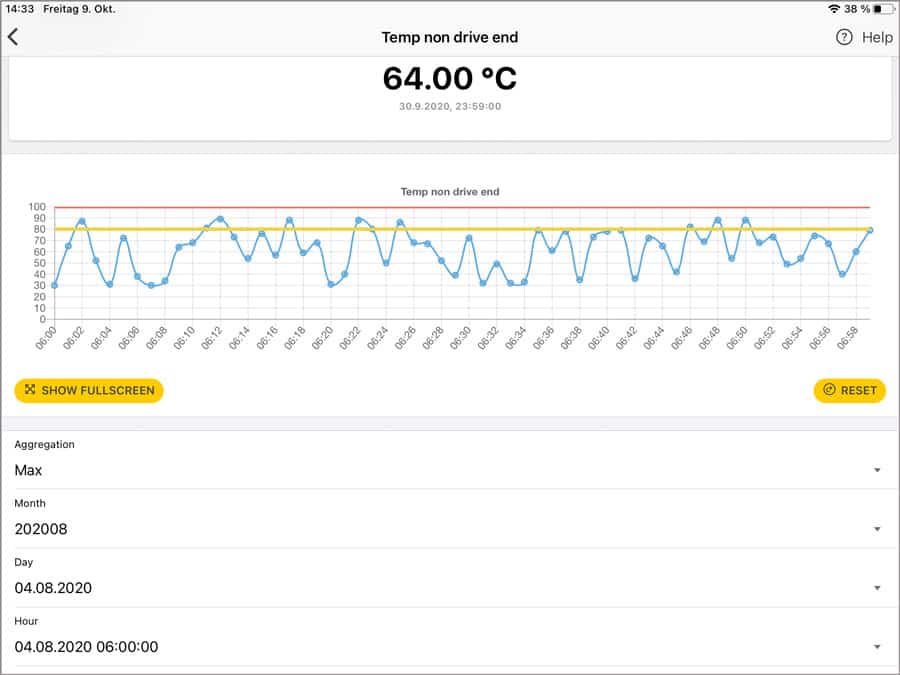

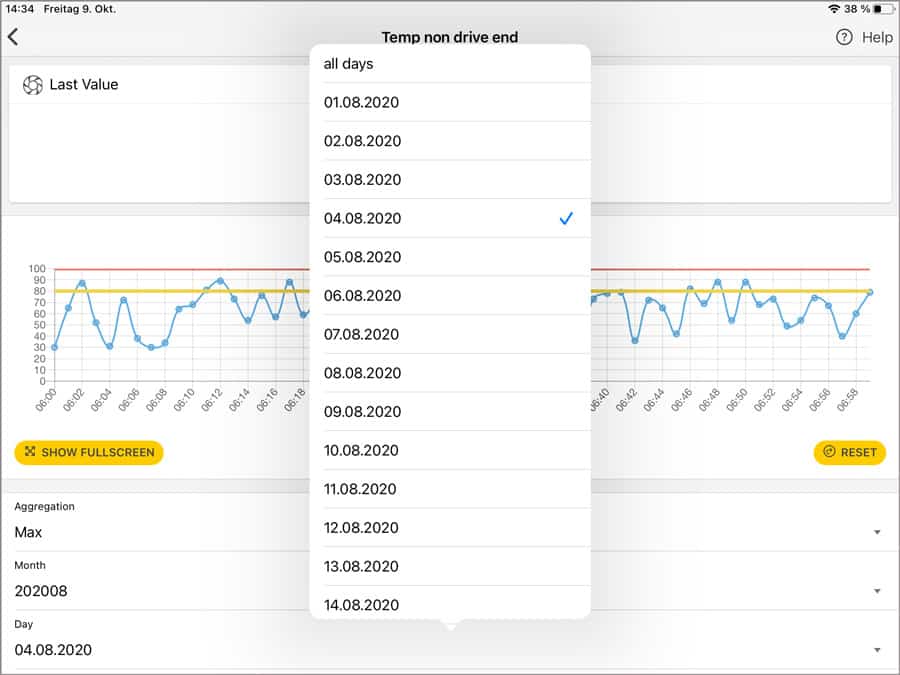

- Easy analysis of measured data

Thanks to simple operation, intuitive user interface and effortless reading of machine data, control rounds can be carried out quickly and easily in the future with the help of FANGUARD®. The data transmitted via WiFi can be conveniently read and evaluated using a mobile device. Thanks to continuous data acquisition, faults can be rectified before the plant breaks down; maintenance measures are carried out in advance and no longer have to be planned.