-

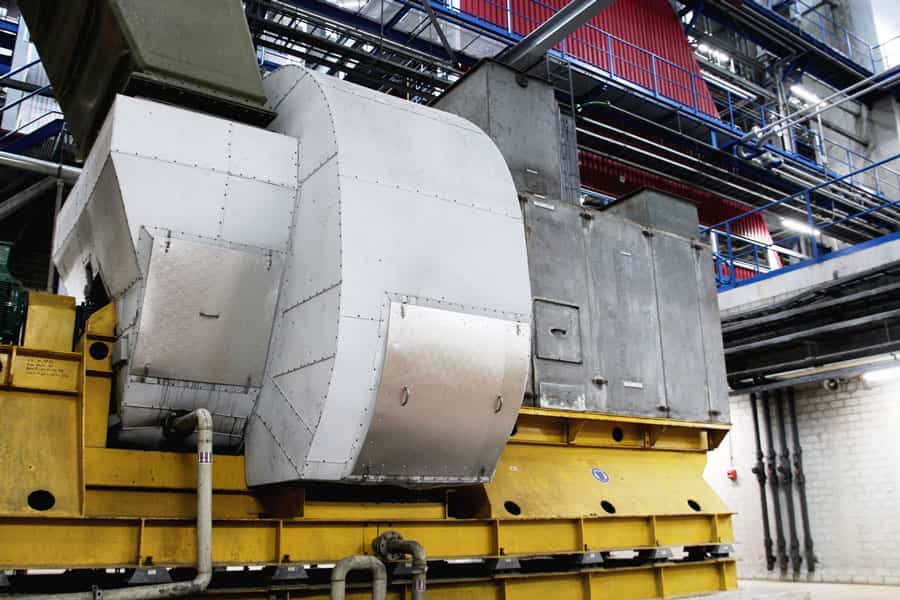

Centrifugal fans in waste incineration

Product application for toxic and explosive gases

Find contact person -

Centrifugal fans in the waste incineration industry

The waste incineration industry is one of the most demanding environments for centrifugal fans. Energy recovery in waste incineration plants depends on efficient and reliable combustion of the waste materials. In this respect, fan performance plays a key role in ensuring optimal conditions for waste incineration.

The aggressive air in waste incineration plants, waste-to-energy plants and sewage sludge incineration plants places special demands on the fan. A great deal of experience is required here for the rezi blowers as well as the combustion air blowers, which use frequency converters in combination with swirl controllers to ensure optimally precise and fast control of the grate incineration. In addition, the induced draught blowers can be adapted to high pressures with simultaneously aggressive process gas mixtures.

In cooperation with POLLRICH, benefit from decades of experience in the waste incineration industry and from the expertise of the market leader for process air fan equipment. Get fans with optimal pressure levels, a wide operating range, and a high longevity of the overall system.

Design

High temperatures and a harsh working environment pose particular challenges to the design of centrifugal fans in waste incineration. Therefore, all materials and individual parts used in the manufacture of the centrifugal fan must be able to withstand extremely high temperatures. In addition, they must also be resistant to the strong resistance of the waste.

Since the operating temperature in waste incinerators is above the normal range, it is essential that durable components and robust bearings are used to provide a solid base for the fan. This requires the use of high quality materials.

In addition, it is necessary that the fan is resistant to corrosion and wear. Accordingly, special surface coating methods are used to protect the machines from corrosion. It is also important to note that fans must be safely installed in hazardous areas. Therefore, it is necessary to consistently comply with ATEX and EEX directives as well as other safety measures.

Compliance with ATEX and EEx directives for explosion protection

Especially in the waste incineration industry, industrial fans are used in potentially explosive atmospheres and must therefore comply with certain strict explosion protection requirements. The ATEX and EEX directives are considered the internationally recognized specifications for the safe and explosion-proof use of centrifugal fans in potentially explosive atmospheres.

ATEX directives refer to protection against explosive atmospheres that may be caused by flammable materials, light liquids, vapor or gaseous substances. This directive establishes criteria for the protection of people, including equipment selection, installation, maintenance and servicing. It also defines individual technologies for protection against explosive atmospheres.

EEx standards regulate protection against explosive environments that may be caused by highly flammable liquids or gases. They establish criteria for equipment selection, installation and maintenance to ensure that all components required to manufacture an industrial centrifugal fan can be used as safely as possible.